As WPC(Wood-Plastic Composite) has risen to popularity quickly, there are so many mounting doubts and questions shrouding this newly developed material. Today, we spend some time on some of the most frequently asked questions about composite material. And hopefully, this will cast some light on it.

For easy access, we’ve arranged these questions into three categories: WPC Product, Installation, and Maintenance. In this article, we focus on commonly asked questions regarding WPC products.

What is Wood-plastic Composite?

Wood-plastic Composite (WPC) is a type of eco-friendly material combining wood fiber with polymers, manufactured with modern technology and production techniques. While possessing a realistic look and texture of real wood, it carries more preferable physical characteristics, making it the best decorative material is known to date.

What is WPC material made of?

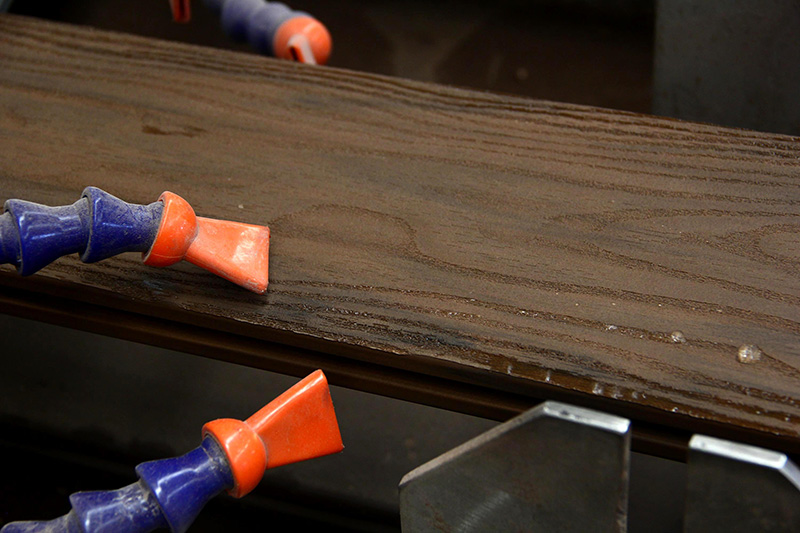

Our WPC material is made from recycled HDPE, poplar wood fibers, and some additives, e.g., lubricants, coupling agents, stabilizers, fillers, biocides, and flame retardants. Other than that, Our capped composite material is also encased with high-density polyethylene plastic through a co-extrusion process.

Is WPC product less harmful to human health than timber?

Yes, it is. Our WPC product doesn’t need painting and staining, which means the toxic substance in the paint is nowhere to be found in your outdoor space. It’s naturally resistant to rot and fungal decay, 100% safe in daily use.

Is the plastic in composite decking toxic?

No. Our WPC product is made from HDPE(high-density polyethylene), a low-health-risk variety of plastics. This plastic is often used for milk or water jugs and won’t give off toxic substances.

Is WPC material waterproof?

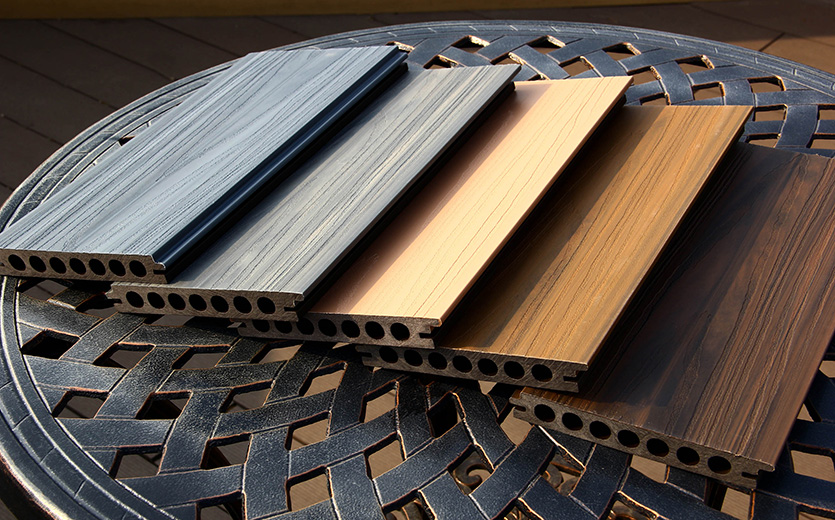

Another good thing about composite decking. It depends on which line of products you’re purchasing. In another word, our composite boards with standard surface and 3D Wood Grain Surface are not 100% waterproof, they’re water-resistant. Capped composite boards are made waterproof, encased completely with a layer of high-grade polymer material. We suggest choosing the one that better suits your needs.

Will composite decking rot, splinter, or decay like wood?

No, that’s where it outperforms timber. According to our test results, our composite material resists rot, splintering, and fungal decay well under harsh conditions.

If WPC product is made from recycled materials, why is it more expensive than wood?

Composite material is more expensive to manufacture. Although most of the raw materials used in manufacturing WPC material are recycled, they’re required to undergo careful processing to ensure a high level of quality and performance. The end result is a product that performs better than timber, lowering your cost over time through lesser maintenance. Timber, on the other hand, requires frequent maintenance and repair after purchase, which ends up with a cost outweighing the “initial investment” in our WPC product.

Does WPC product get hot like pressure-treated wood under the sun?

Another good thing about composite decking. No one can escape heating up under the blazing sun. Our composite material does not get less hot than pressure-treated wood. However, what we can guarantee is that it’ll never warp or bend regardless of how hot it is during the summer. Lighter colored boards tend to be slightly cooler than darker composite boards. On hot days, it’s encouraged to cool surfaces with water or wear appropriate footwear.

Is composite product fire resistant?

Yes, our WPC product possesses a Bfl-s1 fire rating, tested by SGS.

Are WPC products environmentally friendly?

Yes. Above all, timber consumption contributes greatly to deforestation. Therefore, as an ideal alternative for wood, WPC material is made mostly from recycled material, can be recycled again after being used up, and requires no harmful paint. That’s what WPC material can do for the environment.

Will composite decking get mold on it?

It won’t go moldy under normal conditions. However, in rare cases, after being exposed to hot and humid conditions for a long time without care, mold and mildew can appear on the surface but will not penetrate through it. It can be easily removed with bleach and water.

What is the significance of using HDPE to make decking?

It makes WPC material more durable and safe. High-density Polyethylene(HDPE) is a low-health-risk variety of plastics, often found in more rigid products like drinking cups and food packaging. It enables WPC material to have a superior physical and mechanical performance to those with mixed density resins, resulting in a composite material that’s stiffer, more durable, and harder than other ordinary products.

Post a Comment